Start your new career today! APPLY HERE

The machining choice of the heavy equipment industry for over 47 years!

Snyder Industries has an arsenal of machining equipment using the latest technology in multi-tasking machining centers, milling, turning, gear cutting and heat treating with the highest quality control standards.

- Gun Drilling up to 60″ Depth

- Assembly Fabrication

- Internal/External Gear and Spline Cutting

- Heat Treating and Metal Hardening

- ISO9001:2015 Registered

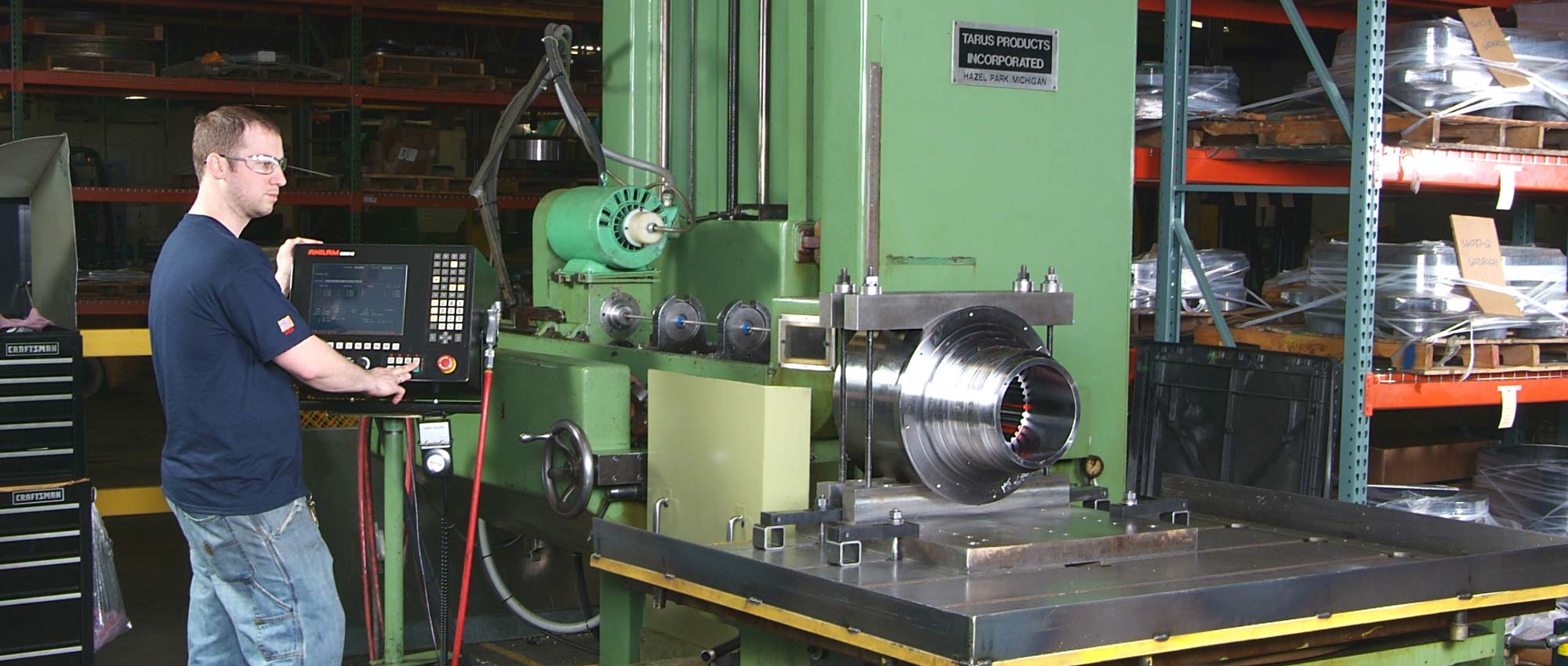

Large Parts Machining

Snyder Industries can provide precision CNC milling and turning on parts as large as 79″ in diameter.

- Gun Drilling up to 60″ Depth

- Internal/External Gear and Spline Cutting up to 51″ OD (outside diameter)

- Turning up to 79″ OD x 61″ OAL (overall length)

- Milling up to 77″ OD x 59″ OAL

- CMM Inspection up to 59″ L x 78″ W x 50″ H

See our equipment and capabilities page for more information.

Gear Cutting

Snyder Industries can provide internal/external gear and spline cutting on rings, shafts, housings, etc.

- CNC Gear Hobbing up to 31.5″ OD

- CNC Gear Shaping up to 51″ OD

See our Gear Cutting, Shaping & Hobbing page for more information.

Metal Treating

A complete metal treating facility is another beneficial aspect of Snyder Industries. Metal treating services include:

- Heat Treating and Metal Hardening up to 3,500 lbs.

- Computer Controlled Atmospheric Heat Treatment

- Surface Combustion Integral Quench Furnaces

- Temper Furnaces

- Induction Hardening (NATCO and TOCCO methods)

- Shot Peening

- Sub-Zero Deep Freeze

- Metallurgical Laboratory

See our Metal Heat Treating & Hardening page for more information.

Complex Parts Of Any Kind

Contract precision machining of complex parts for heavy equipment or industrial equipment including:

- Wheel Housings

- Planetary Cages

- Carburized Sprockets

- Internal/External Gears

- Ring Gears

- Gear Shafts

- Carrier Bearings

See our Products page for images of parts.